BIT MAKE-UP UNIT

MORE SAFETY ON RIGS

ZERO INCIDENTS DURING MAKING OR BREAKING PDC BITS. ZERO INCIDENTS DURING ALL SENSITIVE CONNECTIONS AS RSS TOOLS AND OTHER DOWNHOLE TOOLS.

DRILL BIT MAKE-UP OPERATIONS ON RIGS

On rigs, make-up operations involving PDC drill bits with manual tongs and breaker plates are time-consuming, require a lot of workers and also involve inherent risks.

The innovative bit make-up unit (BMU) offers several advantages over manual make-up procedures with the breaker plate, for instance:

ADVANTAGES OF USING THE BIT MAKE-UP UNIT

IN CONJUNCTION WITH THE IRON ROUGHNECK, THE BIT MAKE-UP UNIT (BMU) BOASTS THE FOLLOWING ADVANTAGES OVER THE CONVENTIONAL MAKE-UP PROCEDURE:

TO DATE, THIS CERTAINLY IS THE SAFEST AND FASTEST KNOWN METHOD OF MAKING UP PDC DRILL BITS.

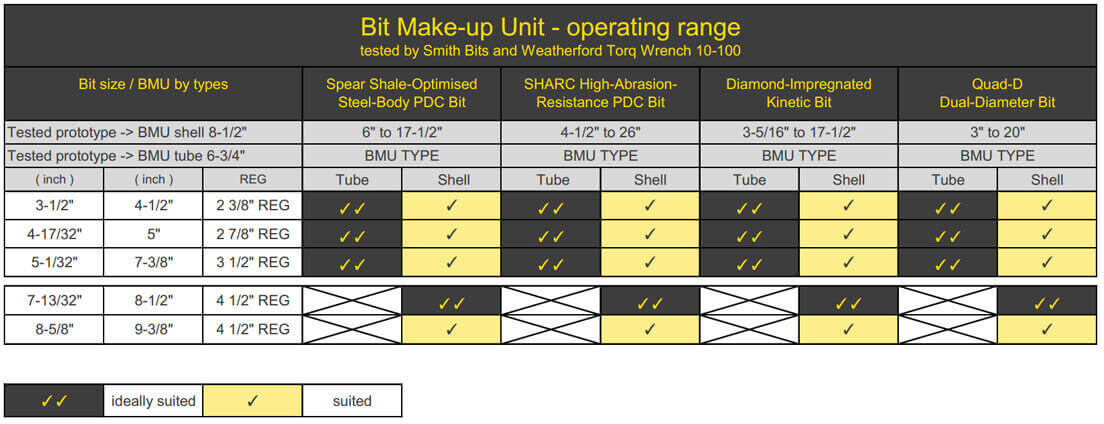

HEAD-TO-HEAD COMPARISON BETWEEN DRILL BIT MAKE-UP MODELS

RIG TONGS VS. BIT MAKE-UP UNIT

CONVENTIONAL DRILL BIT MAKE-UP

For making up a drill bit, the manual tongs are set to the intended diameter. The bit is mounted beforehand, the breaker plate is turned over and the entire unit is then used

in the rotary table. In subsequent make-up operations, the tongs have to be applied manually and, if equired, need to be repositioned or readjusted several times.

During this procedure, it is necessary to have workers under a “suspended load”, i.e. in

a working area specified as the “red zone”.

The time required for one make-up operation including the time for the preliminary online set-up of the rig tongs is approximately 30 to 45 minutes. It can also take significantly longer on cyber rigs, as the use of manual tongs is nowadays no longer a routine operation.

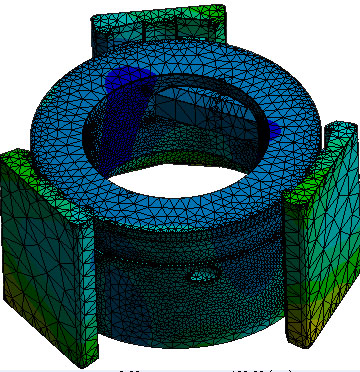

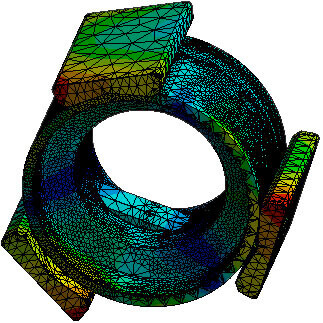

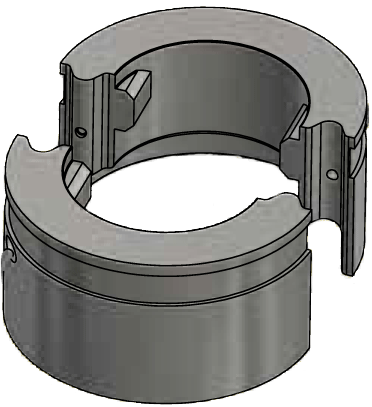

OPTIMISED MAKE-UP PROCESS WITH BMU

The pre-mounted drill bit is subsequently offline fitted into the BMU. The entire unit is thereafter placed into the iron roughneck.

In the following step, the PDC bit is made up in an automated operation by the iron roughneck. After the make-up, the BMU half-shells are removed from the groove of the bit.

During tests, the average time, which is required for making up a drill bit, including the time for the preliminary set-up, was less than 3 minutes.

The time required for the actual make-up procedure with the iron roughneck was less than 1 minute.

GREATER EFFICIENCY AND SAVINGS

The BMU enables a safe and efficient procedure, whereby a drill bit is made up in less than 3 minutes.

Make-up time with

| Manual tongs | 30:00 to 45:00 min. | |

| Bit make-up unit | 03:00 min | |

| Delta | 27:00 to 42:00 min |

How much time can be saved on your rigs and is the use of BMUs in terms of

- cost efficiency,

- irrespective of simultaneous improvements in occupational safety,

- an economically viable option?

Every operator needs to consider these aspects individually.

THE FOLLOWING QUESTIONS SHOULD BE ASKED:

Bitte zur Seite scrollen ->

| Tongs | BMU | |

|---|---|---|

| Risk potential in terms of

occupational safety during make-up operations |

— | + |

| Accuracy of applied torque | — | ++ |

| Documentation of

make-up torque |

— | ++ |

| Risk of damage to drill bit

cutter |

– | + |

| User-friendly for operators | – | ++ |

| Time spent by workers in

the “NO GO” area |

Approx.

30 min. to 45 min. |

< 3 min . |

| Physical effort and strain

during handling |

— | ++ |

| Instruction and training

requirements |

On a regular basis | Intuitive |

| Total duration of make-up

process |

— | ++ |

| Time/expense in preparation

and follow-up activities |

— | ++ |

| Risk potential

Lost in hole |

moderate | low |

CONTACT US

BMU SYSTEMS

MORE SAFETY ON RIGS